The Formula Student Team of the University of Duisburg-Essen has successfully completed a component test at the MESSRING facility on the way to the construction and development of their A40 race car.

Formula Student is an international engineering competition for students initiated by SAE, which has been organized annually by Formula Student Germany e. V. in Germany since 2006. The program gives young engineers the opportunity to gain experience in the fields of design and manufacturing as well as the economic aspects of automotive engineering while participating in national and international events with their self-constructed cars. In 2010, Formula Student added the vehicle class of electric-powered racing cars.

Proud member of Formula Student Electric is the E-Team Duisburg-Essen. Organized as a non-profit association, the team consists of around 60 students who jointly develop their E-racer under the motto #wiePottihnschuf and participate in Formula Student racing events.

“It’s always great to see young, dedicated engineers working on crash testing and vehicle safety. “

Dierk Arp – CEO MESSRING GmbH

The task:

Before racing – just as in industry – it is necessary to undergo technical approval of the safety-relevant regulations relating to the design of the chassis and running gear, as well as the design of the powertrain.

One approval requirement is the testing of a cuboid crash box that protects the driver in the foot area in the cockpit in the event of frontal impact situations.

The test protocol prescribes the following conditions:

- Mass to be braked at least 300kg

- Impact speed 7 m/s

- Absorbed energy at least 7350 joules

- During the test, the acceleration must be measured continuously and then displayed graphically

- Maximum acceleration 40g with average acceleration of maximum 20g

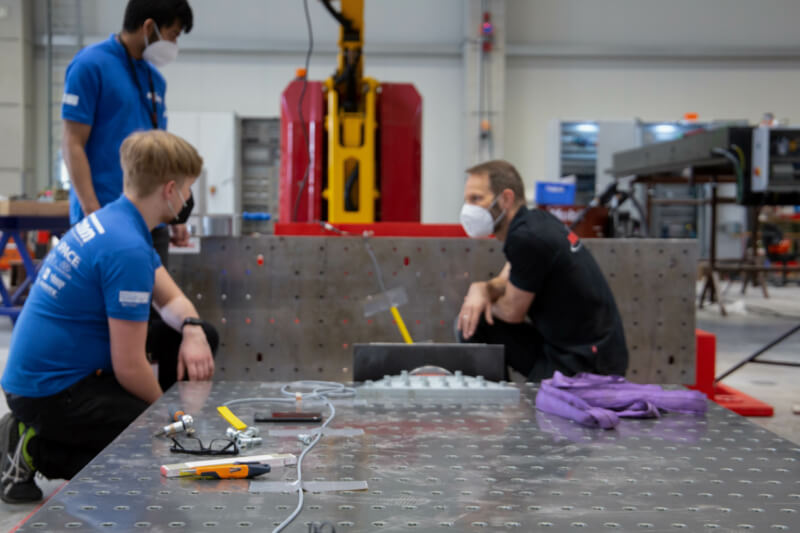

Test preparation

To meet these specifications, the MESSRING team created a sled test setup for the students. The test sled with a total mass of 365 kg including the crash box is attached to a trolley with folding hooks and accelerated precisely to the required 7 m/s in the MESSRING MicroTrack before it crashes into a solid barrier to achieve a controlled collision.

In order to replicate as closely as possible the later deployment location of the crashbox, the box is mounted on a partial replica of the vehicle’s steel tube space frame. This reproduction of the crash box and space frame is then attached to the front of the sled by a flange plate. This allows to subsequently replicate and evaluate the crash effects on the parts of the vehicle structure.

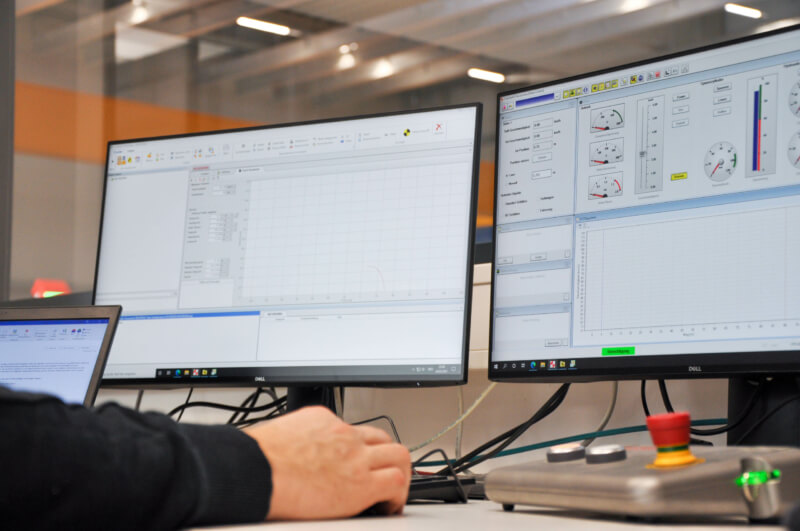

Data acquisition is an essential part of all crash tests: the team installed and calibrated an M=CAM to record high-speed footage for later evaluation. The required lighting for the recordings was provided by the powerful M=LIGHT LEDs which were designed specifically for crash testing.

In addition, the sled was equipped with M=BUS Pro Onboard modules. The crash-proof and compact loggers reliably record and store the sensor data collected during the test.

Test execution

After preparing the test object and the test setup, it’s time for the actual test! But it’s best to have a look for yourselves:

The test was a complete success and the team obviously had fun during the joint execution with the highly motivated students.

The entire MESSRING team wishes the E-Team Duisburg-Essen a successful season and safe driving!